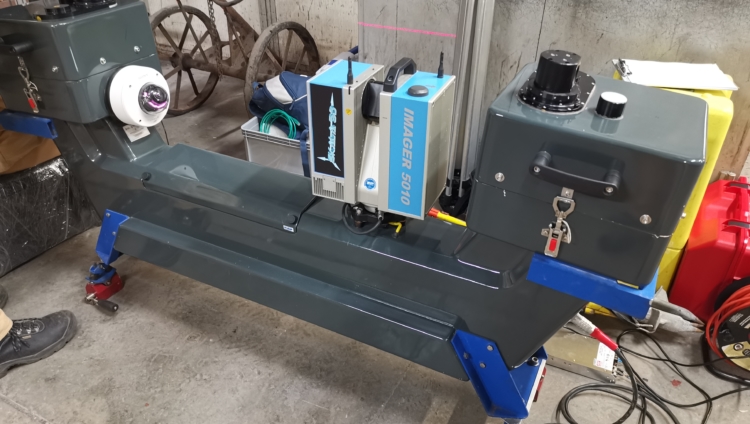

Mining Survey System (MSS)

Mining Survey System (MSS)

The Mining Survey System (MSS) has been designed for and is dedicated to surveys of mine shafts. However, it can also be used everywhere where there is a problem with GPS signal coverage, such as to make measurements in railway tunnels, subway tunnels and horizontal mine workings.

The essence of measurements in a shaft is the following:

- measurement of the geometry of shaft lining and reinforcement elements;

- measurement of the rectilinearity of the conveyance track;

- measurement of the play between the guides and the working surfaces of the slides in the shaft.

The MSS uses terrestrial laser scanning technology and the positioning support systems of the inertial measurement unit (IMU). This allows spatial models of scanned objects to be created with an accuracy of 1-3 mm in a single measurement horizon.

The MSS includes the following:

- Z+F IMAGER 5010 laser scanner;

- 2 Z+F PROFILER 9012 laser scanners;

- Inertial Measurement Unit (IMU) LCI-100;

- Precision Time Source (PTS);

- Set of vibroisolators that prevent the transmission of a part of vibrations occurring during the movement of a conveyance to the measuring system;

- Set of electronic devices to control and monitor the MSS (among others, an industrial laptop);

- Power supply system for the MSS (a battery and converters);

- DSC (Dynamic Scans Calculation) software for specialized measurement analysis.

Visit our profile at Google+

Add us to favorites and keep to date with the last news